Got a question?

Need Help? Call Us Now

+919650835074Thermal Automation Solutions

At Swastik Systems, we specialize in Advanced Thermal Automation Solutions designed to enhance industrial reliability, optimize energy efficiency, and ensure seamless monitoring of temperature-sensitive applications. Our innovative solutions help industries maintain operational excellence by automating thermal processes, reducing downtime, and improving safety standards.

Applications of Advanced Thermal Automation

Over the last 12 Years we made an impact, we have long way to go.

What is Advanced Thermal Automation, and how does it work?

What industries benefit from thermal automation solutions?

How does thermal automation improve equipment lifespan?

Can thermal automation integrate with existing industrial systems?

Key Features of Our Thermal Automation Solutions

Advanced Thermal Automation Solutions for Industrial Safety & Efficiency

✔ Advanced Heat Detection | ✔ Real-Time Monitoring | ✔ Industry-Grade Precision

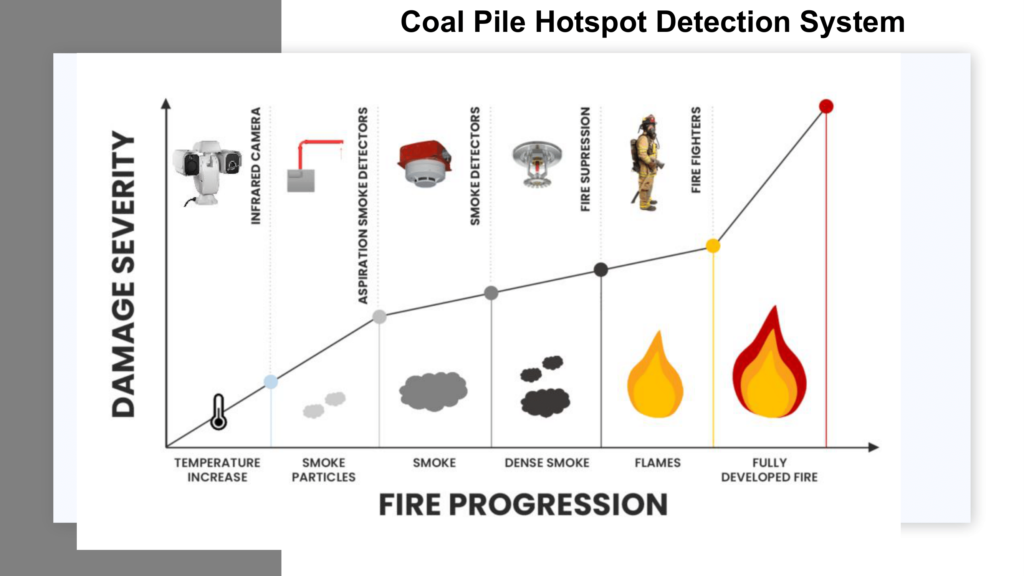

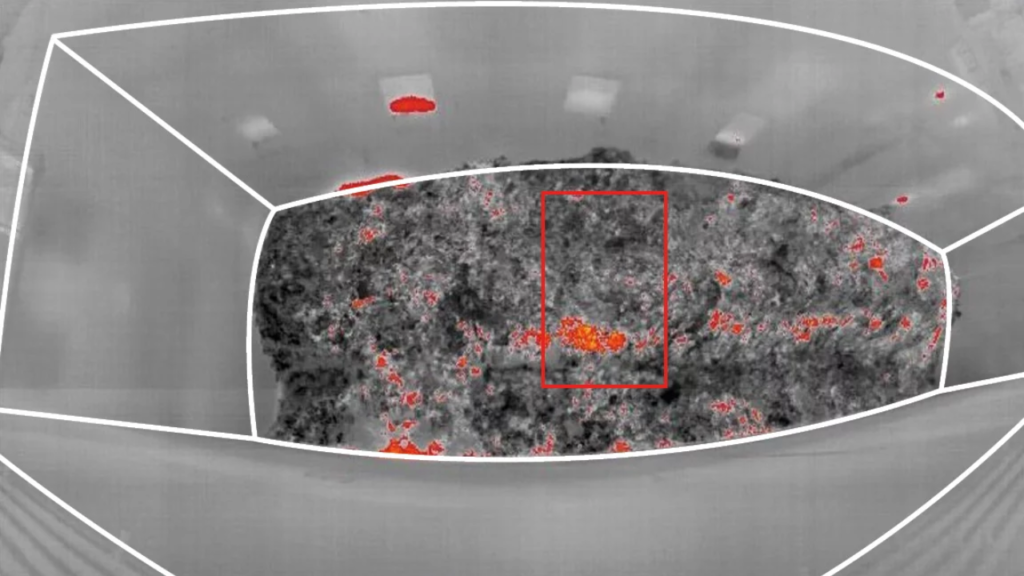

Coal Pile Hotspot Detection System

Our AI-powered thermal imaging solution continuously monitors coal piles to detect and prevent spontaneous combustion. This system enhances safety, reduces fire risks, and ensures operational efficiency in coal storage facilities.

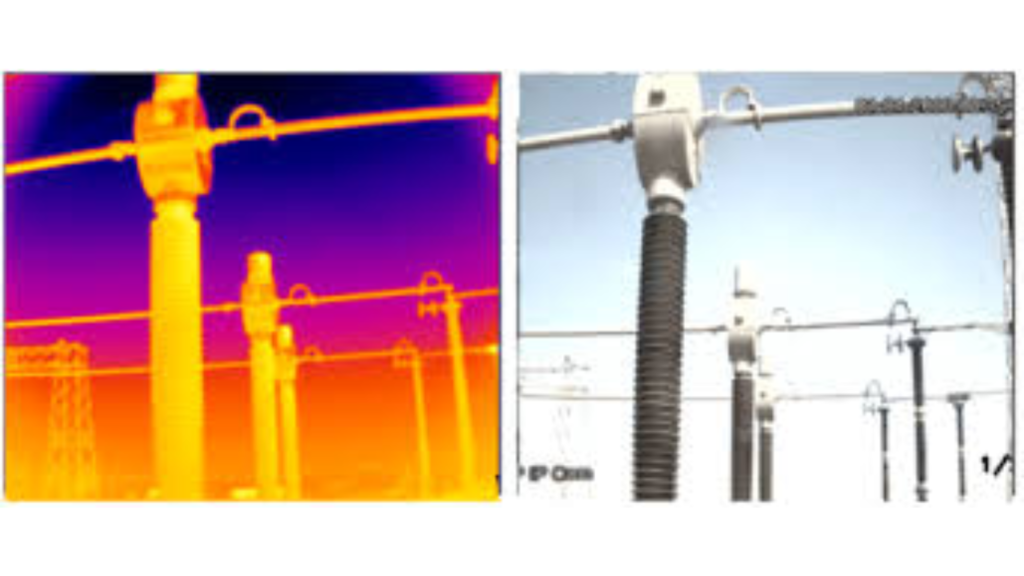

Sub-Station Hotspot Detection System

Designed for power substations, this system identifies overheating in electrical components, preventing failures, short circuits, and equipment damage. Real-time thermal monitoring ensures proactive maintenance and system reliability.

Waste Bunker/AFR Monitoring System

This system provides continuous thermal monitoring of waste bunkers and alternative fuel resources (AFR), ensuring early detection of hotspots and combustion risks. It helps industries prevent hazards and maintain operational safety.

Cement Kiln Shell Monitoring

Our high-precision thermal sensors monitor kiln shell temperatures to prevent heat loss, detect refractory failures, and optimize energy efficiency in cement production. This system helps extend equipment life and reduce fuel consumption.

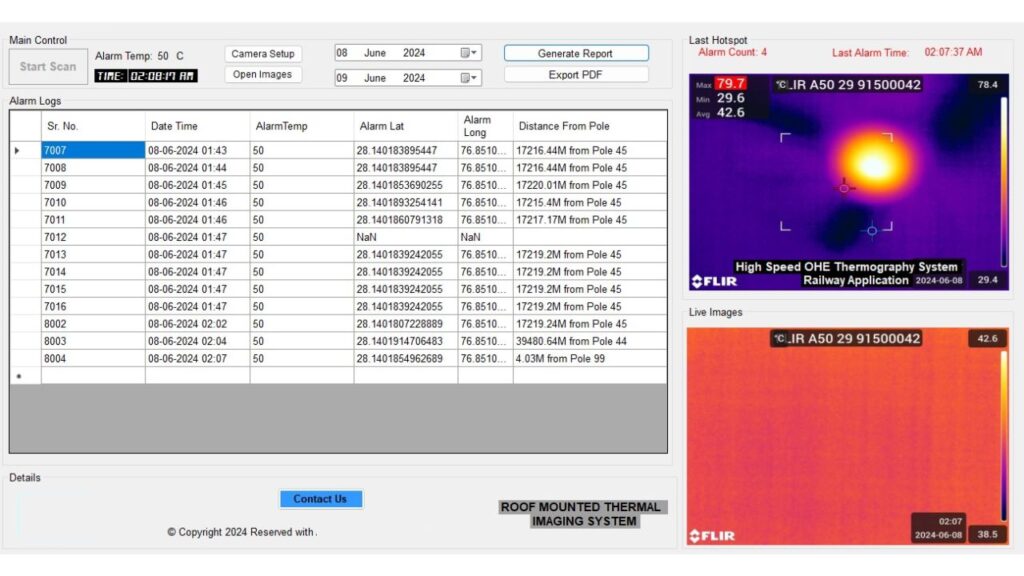

OHE Hotspot Detection System

Specially designed for railways, transmission lines, and power grids, this system identifies hotspots in overhead equipment (OHE), preventing failures, downtime, and power outages through real-time thermal diagnostics.

Ladle and Casting Unit Monitoring

This solution ensures temperature stability in molten metal handling, providing continuous monitoring of ladles and casting units. It helps reduce thermal stress, enhance quality control, and improve workplace safety.

Fire-Sensitive Area Monitoring

Our thermal surveillance system is ideal for high-risk areas prone to fire hazards, such as factories, warehouses, and refineries. It enables early fire detection, reducing risks and improving emergency response times.

AC/DC Motors & Machinery Monitoring

This system provides real-time thermal diagnostics for industrial motors and rotating machinery, detecting overheating, misalignments, and mechanical failures. It ensures predictive maintenance, reducing downtime and repair costs.